Engineering

Method of Orientating Fillers in Polymer Composite Materials

WARF: P09239US

Inventors: Xiaochun Li, Lih-Sheng Turng, Larry Holmes, Yiyan Peng

The Wisconsin Alumni Research Foundation (WARF) is seeking commercial partners interested in developing a method to fabricate polymer composites and nanocomposites incorporating functional and/or reinforcing fillers with multi-directional orientation by design.

Overview

Over the past decade, polymer composites have emerged as a new class of high performance materials with unique and desirable material properties such as strength, weight and rigidity. These composites are made with two or more materials with individual material properties that combine to create a new structure with tailored properties.

To enhance the desired properties, fillers such as fibers or particles may be embedded into the material. Generally, fillers are distributed uniformly throughout the material, providing predictable properties and mechanical response. However, actual spatial distribution and orientation of the fillers is strongly dependent on the manner in which the materials are prepared and processed, and poor preparation may lead to non-uniform distribution and undesirable orientation of filler. Furthermore, since current methods focus on uniform distribution of filler, a finished composite cannot be tailored to have different properties in different locations.

Finished composites that have different properties in different locations are known as functionally graded materials, which vary in composition and structure gradually over their volume. Various processes such as impeller drying, thermal spraying, controlled segregation and controlled blending have been developed to fabricate functionally graded materials, but these processes have drawbacks including small batch size and issues with high quality reproducibility.

To enhance the desired properties, fillers such as fibers or particles may be embedded into the material. Generally, fillers are distributed uniformly throughout the material, providing predictable properties and mechanical response. However, actual spatial distribution and orientation of the fillers is strongly dependent on the manner in which the materials are prepared and processed, and poor preparation may lead to non-uniform distribution and undesirable orientation of filler. Furthermore, since current methods focus on uniform distribution of filler, a finished composite cannot be tailored to have different properties in different locations.

Finished composites that have different properties in different locations are known as functionally graded materials, which vary in composition and structure gradually over their volume. Various processes such as impeller drying, thermal spraying, controlled segregation and controlled blending have been developed to fabricate functionally graded materials, but these processes have drawbacks including small batch size and issues with high quality reproducibility.

The Invention

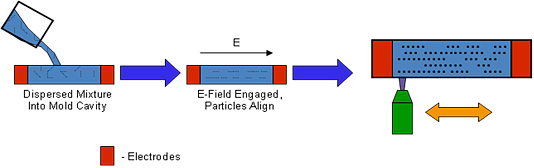

UW–Madison researchers have developed a method for fabricating polymer composites incorporating fillers with multi-directional orientations that allow for the fillers to be orientated in a direction or concentration suitable for a particular composite requirement. After depositing fillers in a matrix material, fillers are aligned by exposing specific portions of the matrix material to an electric field. This alignment creates a pseudo-fiber representative of chains of the filler particles, which is oriented parallel to the electric field direction. The filler particles then are locked into position by hardening of the polymer matrix through UV curing or other means. The process is repeated with pseudo-fiber alignment in desired directions for multiple layers, which are bonded together naturally through the hardening process. This process may be used to create laminated composites with multi-directional filler orientations with natural or synthetic fillers in a variety of shapes. This process also can be easily incorporated with existing rapid prototyping machines and processes to produce parts with significantly improved performance due to the added capability of manipulating the filler orientation and distribution within the matrix material.

Applications

- Functionally graded materials for applications in optical, biological, structural and electrical systems

- Layered processing applications such as rapid prototyping techniques representative of stereolithography

- Small scale manufacturing of composite polymer parts

Key Benefits

- Allows fillers to be oriented in a direction or concentration suitable for specific requirements

- Allows production on a larger scale than current fabrication methods

- Reduces cost and complexity compared to current fabrication methods

- Provides desired changes in mechanical, electrical, optical and/or thermal properties of parts developed with rapid prototyping

Figures