Clean Technology

Producing Liquid Fuels from Biomass-Derived Carboxylic Acids

WARF: P09298US

Inventors: James Dumesic, Juan Carlos Serrano Ruiz, Ryan West

The Wisconsin Alumni Research Foundation (WARF) is seeking commercial partners interested in developing a method to convert inexpensive biomass-derived carboxylic acids into liquid fuels, functional intermediates and solvents.

Overview

Recently, significant advances have been made in using heterogeneous catalysts for converting biomass-derived compounds to chemicals and fuels. One such compound, levulinic acid, can be inexpensively obtained in high yields from a variety of waste cellulose-containing materials.

Conversion of cellulose to levulinic acid is achieved by acidic deconstruction followed by acid-catalyzed dehydration. However, the deconstruction of solid cellulose uses chemical components such as sulfuric acid, which may alter the performance of the catalysts used in the process of converting the levulinic acid to the desired fuels or chemicals. Therefore, a method to convert cellulose to liquid chemicals while avoiding unwanted interaction between the acid and the catalyst is needed.

Conversion of cellulose to levulinic acid is achieved by acidic deconstruction followed by acid-catalyzed dehydration. However, the deconstruction of solid cellulose uses chemical components such as sulfuric acid, which may alter the performance of the catalysts used in the process of converting the levulinic acid to the desired fuels or chemicals. Therefore, a method to convert cellulose to liquid chemicals while avoiding unwanted interaction between the acid and the catalyst is needed.

The Invention

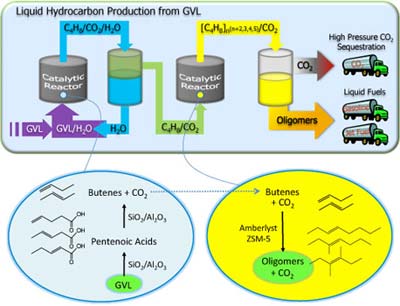

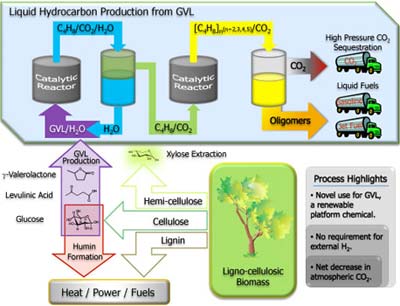

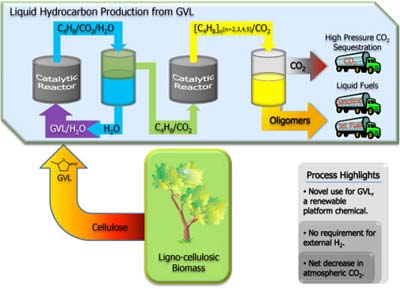

UW-Madison researchers have developed a cascading method to convert cellulose to liquid fuels and other chemical intermediates. The method involves the conversion of aqueous solutions of levulinic acid and other biomass-derived carboxylic acids into gasoline components in a catalytic flow reactor.

The new process allows total conversion of levulinic acid into pentanoic acid, 5-nonanone or butene in a single reactor without the need for expensive separation technology. These products can be converted to liquid fuels (e.g., C4, C9 and/or C18 alkenes) via catalytic upgrading methods. The cascade approach provides a strategy for management and recycling of sulfuric acid in the cellulose degradation step, while minimizing the need for an external hydrogen source. Current processes achieve only 70 percent conversion and require complicated separation procedures.

The new process allows total conversion of levulinic acid into pentanoic acid, 5-nonanone or butene in a single reactor without the need for expensive separation technology. These products can be converted to liquid fuels (e.g., C4, C9 and/or C18 alkenes) via catalytic upgrading methods. The cascade approach provides a strategy for management and recycling of sulfuric acid in the cellulose degradation step, while minimizing the need for an external hydrogen source. Current processes achieve only 70 percent conversion and require complicated separation procedures.

Applications

- Converting cellulose or levulinic acid to pentanoic acid, 5-nonanoe and butene, which can be used as solvents, fuel additives and fuels

- Coupling with the industrial production of levulinic acid through the inexpensive Biofine process to convert renewable lignocelluloses resources to liquid fuels

Key Benefits

- Allows conversion of cellulose to liquid fuels without requiring costly purification steps

- Converts cellulose to levulinic acid at higher yields than current methods

Additional Information

Related Intellectual Property

Publications

For current licensing status, please contact Jennifer Gottwald at [javascript protected email address] or 608-960-9854

- Kunkes E.L., Simonetti D.A., West R.M., Serrano-Ruiz J.C., Gärtner C.A. and Dumesic J.A. 2008. Catalytic Conversion of Biomass to Monofunctional Hydrocarbons and Targeted Liquid-Fuel Classes. Science 322, 417-421.

Figures