Research Tools

Microfluidic Device for Rapid Nucleic Acid Isolation and Purification

WARF: P100050US01

Inventors: David Beebe, Scott Berry

The Wisconsin Alumni Research Foundation (WARF) is seeking commercial partners interested in developing a device and method for extracting and purifying nucleic acids from biological materials.

Overview

Extraction and isolation of nucleic acids from biological samples is an essential prerequisite for further amplification, detection and quantification of specific genetic sequences. The first step in the extraction process is lysing, or disintegration, of the cells with detergents, enzymes or grinding and homogenization, resulting in a mixture of nucleic acids, cellular debris and extraction reagents. The nucleic acids then are separated and purified using a variety of techniques including organic solvent extraction, chromatography, centrifugation and dialysis.

The purification step can require multiple time-consuming and tedious washing steps. Commercially available nucleic acid isolation kits require from 15 minutes to more than an hour to complete, and it has been suggested that as much as 15 percent of all molecular biology research time is devoted to purification. A method or device to reduce the time associated with isolating nucleic acids from a biological sample is needed.

The purification step can require multiple time-consuming and tedious washing steps. Commercially available nucleic acid isolation kits require from 15 minutes to more than an hour to complete, and it has been suggested that as much as 15 percent of all molecular biology research time is devoted to purification. A method or device to reduce the time associated with isolating nucleic acids from a biological sample is needed.

The Invention

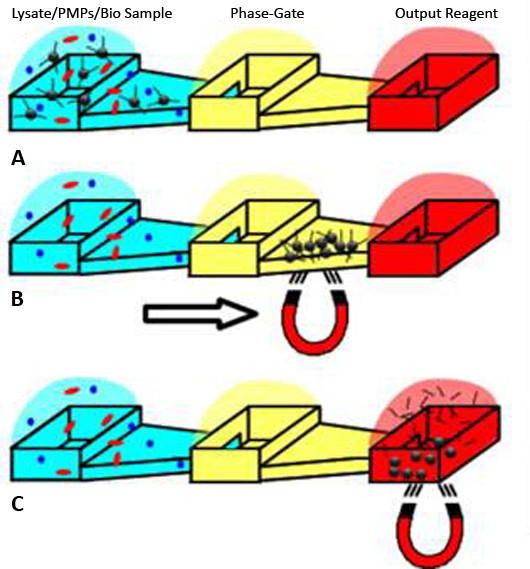

UW-Madison researchers have developed a microfluidic device and method for rapidly extracting and purifying nucleic acids from biological materials. The device includes an input zone for receiving the biological sample, a phase-gate zone for holding an isolation buffer and an output zone for receiving a reagent. The isolation buffer consists of oil that acts as a phase-gate and prevents unwanted material from passing through to the output well. The device employs an isolation mechanism using paramagnetic particles (PMPs), which preferentially bind the nucleic acids, and a lysis buffer, which inhibits the polymerase chain reaction until the nucleic acids have been isolated.

The isolation method proceeds through three main steps. First, the lysis buffer and PMPs are added to the biologic sample in the input well. Then, a magnetic field is used to draw the bound nucleic acid/PMPs through the phase-gate and into the output well, a process that lasts around 15 seconds. This simple phase-gate step replaces the multiple washes required in current methods. Finally, the nucleic acid/PMP reagent is collected for processing via polymerase chain reactions.

The device and method are configured to maximize isolation and purification of nucleic acids while maintaining compatibility with existing multiwell plates and liquid-handling robotic systems. Isolation and purification using this invention can be accomplished in approximately five minutes, including separation, device loading and sample collection. This provides a vast improvement over current kits, which require multiple washing steps and 15 to 45 minutes for purification.

The isolation method proceeds through three main steps. First, the lysis buffer and PMPs are added to the biologic sample in the input well. Then, a magnetic field is used to draw the bound nucleic acid/PMPs through the phase-gate and into the output well, a process that lasts around 15 seconds. This simple phase-gate step replaces the multiple washes required in current methods. Finally, the nucleic acid/PMP reagent is collected for processing via polymerase chain reactions.

The device and method are configured to maximize isolation and purification of nucleic acids while maintaining compatibility with existing multiwell plates and liquid-handling robotic systems. Isolation and purification using this invention can be accomplished in approximately five minutes, including separation, device loading and sample collection. This provides a vast improvement over current kits, which require multiple washing steps and 15 to 45 minutes for purification.

Applications

- Molecular biology research requiring extraction and purification of nucleic acids

Key Benefits

- Simpler assembly

- Higher throughput of purified nucleic acids, resulting in fewer cycles for detectable amplification

- Reduced material volume and cost

- Reduces time required for isolation and purification by more than 65 percent

- Compatible with existing multiwell plates and liquid-handling robots

Stage of Development

The development of this technology was supported by WARF Accelerator. WARF Accelerator selects WARF's most commercially promising technologies and provides expert assistance and funding to enable achievement of commercially significant milestones. WARF believes that these technologies are especially attractive opportunities for licensing.

Additional Information

For More Information About the Inventors

Related Intellectual Property

Tech Fields

For current licensing status, please contact Jeanine Burmania at [javascript protected email address] or 608-960-9846

Figures